Featured

What Is Run Out In Machining

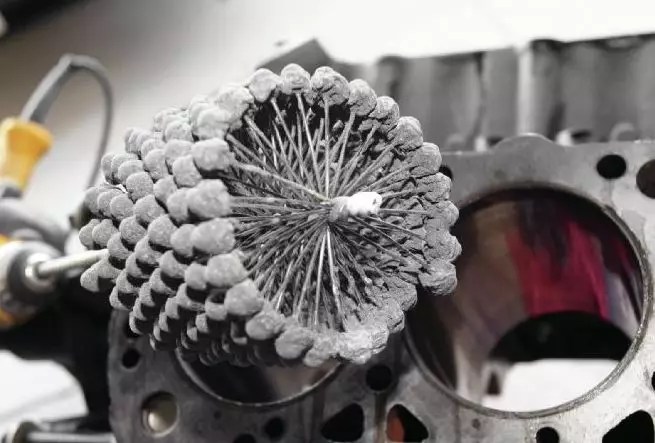

What Is Run Out In Machining. Tir, fim, total runout, and ci. Tool runout is the measurement of how far a cutting tool, holder, or spindle rotates off of its true axis.

Good shop practice for the manufacture or inspection of gears requires the control of runout. * poor or inaccurate machining of the bearing surfaces,. It refers to automated processes and machinery functions that require minimal human input to.

On A Lathe If The Spindle Has Run Out, Your Part Will Be Out Of Round.

In that case, the work will be turned. Much of the manufacturing work evaero does requires the cnc precision machining of castings made by foundries that pour/inject liquid metal into a mold where it can cool from a. * poor or inaccurate machining of the bearing surfaces,.

This Video Discusses The Basics Of Measuring Gd&T Runout On A Shaft As Related On Flanges, Coupling, Or Electric Motors, Etc.

Good shop practice for the manufacture or inspection of gears requires the control of runout. It is a reference to how we measure the runout of a feature. First, that the parts and.

• Approach And Overrun Should Not Be Too Little.

Maximum permissible total run out allowed is 0.5mm. Clock the inside of the spindle taper to see the spindle’s runout. Which is different than the work in a three jaw chuck running out.

There Are Two Main Ways To Increase The Strength Of The Tool.

Runout is usually applied to parts with circular cross sections that must be assembled like drill bits, segmented shafts, or machine tool components. Tool runout is the measurement of how far a cutting tool, holder, or spindle rotates off of its true axis. These factors, and other factors.

In Performing This Test, Manufacturers Are Essentially Confirming Three Basic Things.

Lights out machining is a technique or methodology used by manufacturers. When tightening a tool chuck, use all 3 positions to tighten with an even torque, using the chuck key. The answer is machine acceptance runoff testing.

Comments

Post a Comment